Links:

Selection and Maintenance

1. Unusual Noises One of the primary indicators of a failing timing belt is a loud ticking or tapping sound coming from the engine. This noise often suggests that the belt may be slipping or that the timing has gone off.

4. Electronic Controls Advanced control systems can be employed to precisely manage motor speed and torque. These systems often involve feedback loops that monitor performance and adjust settings in real time.

Advantages

The quality and reliability of automotive parts are paramount. They must meet stringent safety and performance standards to ensure that vehicles operate efficiently and safely. Not only do high-quality parts enhance vehicle performance, but they also minimize the risk of breakdowns and accidents, which can have serious consequences. As vehicles become more technologically advanced, the demand for high-quality, durable automotive parts has increased significantly.

Variable belt drives have found applications in a myriad of industries. In the automotive sector, they are commonly used in continuously variable transmissions (CVTs), which optimize engine performance and fuel efficiency by providing seamless transitions between gear ratios. This technology allows for smoother acceleration and improved fuel economy compared to traditional fixed-gear systems.

For those interested in purchasing a Honda Civic Hatchback, a wealth of resources is available online. Automotive websites and dealerships often feature extensive listings with images that showcase the car's various trims, colors, and features. Searching for Honda Civic Hatchback for sale will yield numerous results, including both new and used options to fit different budgets.

From a design perspective, the notch joined belt embodies a modern aesthetic that appeals to a wide audience. It is available in various materials such as leather, fabric, and synthetic blends, allowing for versatility in both style and texture. Whether paired with jeans, tailored trousers, or a breezy summer dress, this belt complements diverse outfits, enhancing the overall look without overshadowing it. Many designers have embraced this concept, offering belts adorned with intricate patterns, unique colors, and innovative textures that contribute to their appeal.

- Convenience and Comfort Unlike invasive procedures or professional treatments, the V Face Lift Massager Belt offers an easy, at-home solution that can be enjoyed anytime. Its lightweight design makes it easy to use while watching television, reading, or relaxing.

2. Visible Cracks or Fraying Inspecting the belt for signs of physical damage can help identify deterioration.

The latest iterations of the Space Wagon have also included modern safety technologies, such as lane departure warning systems and collision avoidance systems. These advancements not only enhance safety but also make driving a more pleasant experience, allowing drivers to focus on the road ahead with confidence.

Understanding the different types of poly V belts and their applications is essential for anyone involved in automotive and industrial operations. Their versatility, efficiency, and durability make them indispensable components in modern machinery. By selecting the right type of poly V belt and following proper maintenance practices, you can ensure optimal performance and extend the lifespan of your equipment.

3. Reduced Risk of Failure The robust design and material choice lessen the chance of breakage or failure, which could lead to significant engine damage.

The Case for Oil

Mitsuboshi A Legacy of Innovation

3. Thay Thế Đúng Thời Điểm Thay thế dây curoa quạt theo đúng lịch trình mà nhà sản xuất khuyến nghị. Đừng chờ đến khi có vấn đề xảy ra mới quyết định thay thế.

As technology continues to evolve, the future of automatic belts holds exciting possibilities. Innovations such as smart belts are already emerging, featuring integrated technology that can track fitness metrics or adjust based on body movements. Imagine a belt that not only fits perfectly but also monitors your activity levels—this is the next frontier in wearable technology.

Signs of Wear and Tear

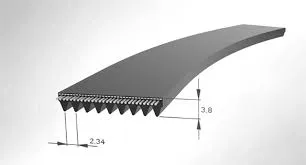

In summary, the A Toothed Flat Belt Drive is a sophisticated yet simple design that offers numerous advantages in power transmission. Its unique features allow for efficient operation across various applications, making it an indispensable component in the machinery of numerous industries. As technological advancements continue, the role of such belt drive systems will undoubtedly expand, contributing to enhanced productivity and efficiency in mechanical processes.

What is an Engine Drive Belt?

2. CNC Machines Computer Numerical Control (CNC) machines utilize stepper motors with belts to move cutting tools accurately along multiple axes. This ensures precise machining and manufacturing processes.

1. Three-Point Seat Belts Most cars come equipped with three-point seat belts, which offer safety and comfort. Replacement costs for these belts depend largely on the vehicle's design and the manufacturer of the seat belt. Brands known for luxury cars tend to charge more for replacement due to the complexity involved, which can result in pricing anywhere from $50 to $300.

Conclusion

2. Tension Checks Ensure proper tension is maintained. Both over-tensioning and under-tensioning can lead to premature wear or slippage.

2. Consistency and Quality Control Automated processes reduce the likelihood of human error, leading to more consistent product quality. Advanced monitoring systems allow manufacturers to maintain strict quality control standards throughout the production line.

rubber fan belt making machine

Types of Motorbike Belts

1. Brand Not all timing belts are created equal. Renowned brands such as Gates, Bosch, and Dayco may offer better quality and longer warranties than generic brands. However, this often comes at a higher price. It’s essential to weigh the reputation of the brand against your budget.

In the realm of machinery and equipment, the efficiency and reliability of components play a crucial role in determining overall performance. One such essential component that has garnered attention in various industries is the 8PK belt. This article delves into the specifics of the 8PK belt, exploring its design, applications, and significance in mechanical systems.

The serpentine belt is a long, continuous belt that winds through multiple pulleys. It is responsible for driving various engine accessories simultaneously. Most modern vehicles utilize the serpentine belt due to its efficiency and space-saving design. However, over time, serpentine belts can wear and stretch, leading to decreased performance. Signs of a failing serpentine belt include squeaking noises, visible cracks, or fraying edges.

1. Enhanced Control The most apparent advantage of variable speed belts is the enhanced control they provide over mechanical systems. This adaptability allows operators to set and adjust the speed as needed, responding to changes in workload demands in real time. Whether it's in manufacturing, material handling, or automotive applications, this capability ensures optimal performance and efficiency.

Importance of the 4PK Belt

Customization and Flexibility

v belts manufactures

1. Type of Belt There are different types of belts available, including standard rubber belts and premium belts made of advanced materials that resist wear and tear. Premium belts tend to be more expensive, usually priced at the higher end of the range.

V-belts are named for their trapezoidal cross-section, which resembles the letter V. This design enables V-belts to fit snugly into the grooves of sheaves or pulleys, ensuring a strong grip during operation. The primary function of a V-belt is to transmit power from one shaft to another, typically in mechanical systems that require a high level of torque transmission.

1. Regular Inspections Check for signs of wear, such as frayed edges or cracks, regularly to prevent unexpected failures.

Timing belts typically have a lifespan of about 60,000 to 100,000 miles, depending on the make and model of the vehicle, as well as driving conditions. Regular maintenance and timely replacement of the timing belt are essential to avoid significant mechanical failures. Many vehicle manufacturers recommend replacing the timing belt as part of routine maintenance, often during the ten-year or 100,000-mile service interval.

timing belt function

Understanding Timing Belt Size 535-5M-15 Key Aspects to Consider

While ribbed drive belts are designed for durability, regular maintenance is still essential to ensure their optimal performance. Users should periodically inspect the belts for signs of wear, such as cracks, fraying, or glazing on the ribs. Replacing worn or damaged belts promptly can prevent more significant mechanical failures and costly repairs down the line.

5. Packaging and Distribution Once tested, the belts are packaged and distributed to suppliers or directly to customers across various industries.

Fan belts are elongated loops made from reinforced rubber and are designed to transfer power from the engine’s crankshaft to numerous accessories, including the alternator, water pump, power steering pump, and air conditioning compressor. Their primary function is to ensure that these components operate efficiently, contributing significantly to the overall performance of the vehicle or machinery. Over time, fan belts can wear down due to constant friction, exposure to heat, and environmental factors, necessitating regular inspection and replacement.

Types of Poly V Belts

Pasek klinowy 10PK to z pozoru niewielki, aczkolwiek niezwykle ważny element w każdym pojeździe. Jego rolą jest nie tylko przekazywanie energii, ale również dbanie o efektywność silnika oraz bezpieczeństwo jazdy. Dlatego warto inwestować w dobrej jakości produkty oraz regularnie kontrolować stan techniczny tego kluczowego elementu systemu napędowego. Dzięki temu możemy cieszyć się niezawodnością naszego samochodu przez dłuższy czas.

Rubber V belts have been a cornerstone of mechanical engineering and industrial applications for decades. These essential components offer a reliable means of transmitting power between rotating shafts, making them indispensable in various machines and equipment. Their unique design, combined with the elasticity and robustness of rubber, allows for effective performance in challenging environments.

Moreover, the PK belt has seen a surge in popularity among fashion influencers and celebrities. Social media platforms, particularly Instagram and TikTok, have played a significant role in showcasing how this accessory can enhance personal style. Influencers often demonstrate various ways to wear the PK belt, from cinching oversized shirts to adding definition to flowy dresses. This adaptability not only showcases the belt's functionality but also encourages creativity in fashion.

![Install new belt]()

In recent years, the conveyor belt industry has witnessed significant technological advancements. Smart conveyor systems equipped with IoT (Internet of Things) capabilities allow for remote monitoring and predictive maintenance, reducing downtime and enhancing operational efficiency. These systems can analyze data in real-time, informing operators of any potential issues before they escalate into costly breakdowns.

Conclusion

One of the most significant advantages of HNBR rubber timing belts is their high heat resistance. Traditional timing belts made from regular rubber can succumb to thermal degradation at elevated temperatures. HNBR, on the other hand, can withstand temperatures reaching up to 150°C (302°F) without losing its mechanical properties. This makes HNBR timing belts ideal for high-performance applications where engines often produce substantial heat.

Benefits of Using an Abdominal Belt

6. Aftermarket vs. OEM Parts